Protective coatings have played a vital role throughout history, shielding everything from ancient ships to modern skyscrapers. From early materials like tar and beeswax to today’s advanced nanotechnology, the journey of protective coatings has been long and filled with innovation. Now, a recent breakthrough in this field is again transforming the industry: DragX, a cutting-edge nanotechnology coating.

A Brief History of Protective Coatings

The use of protective coatings dates back to 5,000 BC when ancient civilizations began experimenting with various substances to protect their valuable possessions. Early methods included using tar and clay to waterproof boats and buildings, ensuring longevity and durability. As time progressed, different cultures developed unique solutions, such as the Egyptians’ use of beeswax and clay, and the creation of lacquers and varnishes in ancient Asia.

The Industrial Revolution marked a significant turning point in the evolution of coatings. With the rise of mass production, the demand for anti-corrosive and special-purpose coatings surged. The 19th and 20th centuries saw the development of more sophisticated materials like fusion bonded epoxies (FBE) and multi-layer coating systems. These advancements paved the way for modern protective coatings, which are now essential for everything from pipelines to aerospace.

The Nanotechnology Revolution: Enter DragX

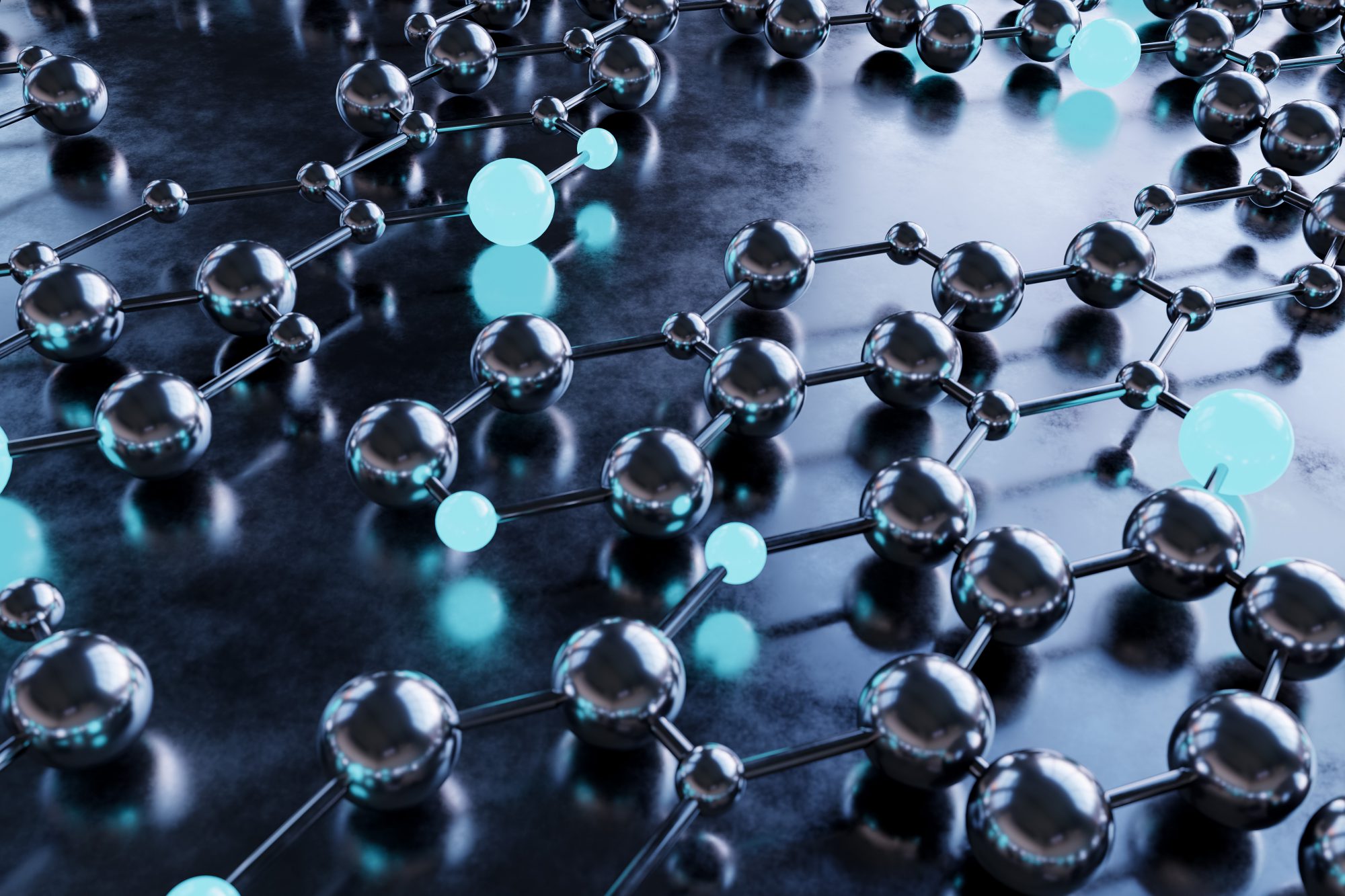

In the 21st century, nanotechnology has emerged as the next frontier in protective coatings. Among these advancements, DragX stands out as a game-changer. This revolutionary nanotechnology coating offers unparalleled protection against corrosion, chemicals, moisture, and UV radiation. What makes DragX truly remarkable is its ability to form a robust, durable shield at the molecular level, providing superior resistance to environmental hazards.

DragX utilizes the power of graphene, a groundbreaking material known for its exceptional strength and conductivity. By incorporating graphene into its formula, DragX creates a coating that protects and enhances the performance of the underlying material. This makes it an ideal choice for industries that require high levels of durability and reliability, such as oil and gas, automotive, and marine applications.

Why DragX is the Future of Protective Coatings

The benefits of DragX are numerous. First and foremost, its nanotechnology base allows for a thinner, lighter coating that doesn’t compromise strength or durability. This is particularly advantageous for industries where weight and efficiency are critical. Additionally, DragX’s hydrophobic properties ensure that surfaces remain dry, reducing the risk of corrosion and extending the lifespan of the coated materials.

Another key advantage of DragX is its versatility. Whether it’s being used to protect pipelines from harsh chemicals or to shield aircraft from UV damage, DragX adapts to the needs of the environment, providing a customized solution for each application.

The Future is Now with DragX

As we look to the future, it’s clear that the role of protective coatings will continue to expand. With innovations like DragX leading the way, industries can expect even greater protection, efficiency, and longevity from their assets. This nanotechnology advancement is not just a coating; it’s a revolution in how we protect and enhance the materials that build our world.

DragX represents the pinnacle of protective coatings technology. Its nanotechnology-driven formula offers unprecedented protection and performance, making it an essential tool for any industry looking to safeguard its assets in the most efficient way possible. As the latest chapter in the long history of protective coatings, DragX is poised to shape the industry’s future for years to come. Learn more here.