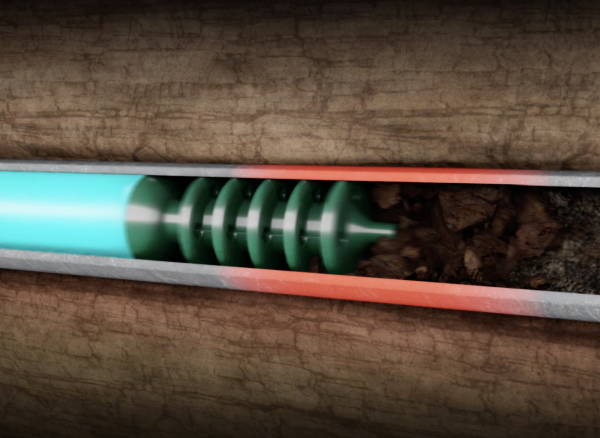

DragX can be applied in-factory or in-situ via a revolutionary pigging system that evenly applies DragX surface treatment to existing, in-place pipelines and tubular. In-situ application is possible for long pipeline segments of any diameter by only accessing the ends of the line. Oceanit has perfected the process of in-field surface preparation and DragX nanocomposite application from proven in-situ coating procedures.

Oceanit’s in-situ coating system is a novel process for applying surface treatment to existing (in-place) pipelines to significantly revitalize performance and throughput. DragX’s advanced nanocomposite is applied in ultra-thin layers, evenly creating an ultra-slick, low-surface-energy pipe ID to reduce friction loss, increase flow, lower energy consumption, and prevent the deposition of debris and contaminants.

DragX has proven the effectiveness of modified PIG batch application techniques, uniformly applying in-field on virtually any pipeline diameter and on pipelines of 20 miles or more in length. Such in-situ application requires minimal surface preparation and is completed without pipe disassembly or re-installment.

DragX can be applied using progressive pigging or spraying techniques. After pipeline proving and cleaning, DragX layers are applied, with the pipe being purged with dry air between coats.

Unlike traditional epoxies, DragX has an easy-to-manage pot life of 72 hours after mixing, a rapid cure time once applied (1-2 hrs. at ambient temperatures), and is effective at thicknesses of just 2mil, meaning it is ideal to work with for in-situ rehabilitation in short periods of downtime.

DragX application is quality controlled with Oceanit’s RIVEAL system, which stands for “Rapid Inspection & Visual Evaluation with AI-based Logging. RIVEAL is an AI-driven platform technology for rapid inspection using multi-spectral surface data analysis. The system uses data captured from Oceanit’s novel PiggyBack: an intelligent PIG system for pipeline inspection.

PiggyBack is a smart PIG that travels a pipeline like a normal PIG, but captures qualitative surface data along the pipe. Piggyback combines multi-spectral imaging with on-board INS (Inertial Navigation System) for precise geolocation data.

Data from PiggyBack is imported to the RIVEAL platform where it is “unwrapped” and analyzed at blistering speeds. RIVEAL uses a proprietary computer vision AI to process miles of pipeline data or thousands of tubulars in just minutes.

RIVEAL identifies surface anomalies and defects, flagging trouble areas and allowing operators or maintenance crews to focus only on areas needing intervention. RIVEAL provides reliable quality control information on the application of DragX.

Utah State University Pipe Friction Loss Case Study

Deployments

- Demonstration with the Colorado School of Mines, in conjunction with the RPSEA program with the NETL, for anti-hydrate plugging performance.

- Deployment with the Colorado School of Mines for asphaltene repulsion performance.

- Field implementation in Houston, TX, in partnership with the U.S. Department of Energy to protect natural gas transport pipelines against corrosion and methane leakage.

- Field Applications with major Oil & Gas operators for midstream, downstream, and chemical handling pipeline applications.

- Field Application with water distribution test facility for reclaimed ductile iron and mortar-lined water main pipes, compatible with water quality standards and sanitization protocols (exposure to chlorine flushes).

Key Benefits

- Improves pipeline efficiency by reducing surface friction of the pipe wall

- Increases flow throughput by 20% or more

- Is effective for all flow regimes and products (Liquid, gas and multi-flow)

- Reduces pressure loss

- Maintains flow capacity for de-rated pipelines

- Reduces buildup of contaminants such as waxes and asphaltenes on pipe walls

- Reduces the formation of black power

- No adverse effects on the purity of the fluids transported

- Faster pigging & less frequent scraping

Contact Us

Would you like to learn more? Contact us to learn how DragX surface treatment can help you proactively manage risks, rehabilitate degrading lines, and keep your production flowing.