Pipelines have been essential for transporting fluids across long distances, but energy consumption remains a challenge. Reducing drag and friction inside pipes can significantly lower energy costs and decrease carbon footprints. One exciting solution is the application of hydrophobic coatings, and this is where DragX, a revolutionary surface treatment, shines.

How Hydrophobic Coatings Reduce Drag

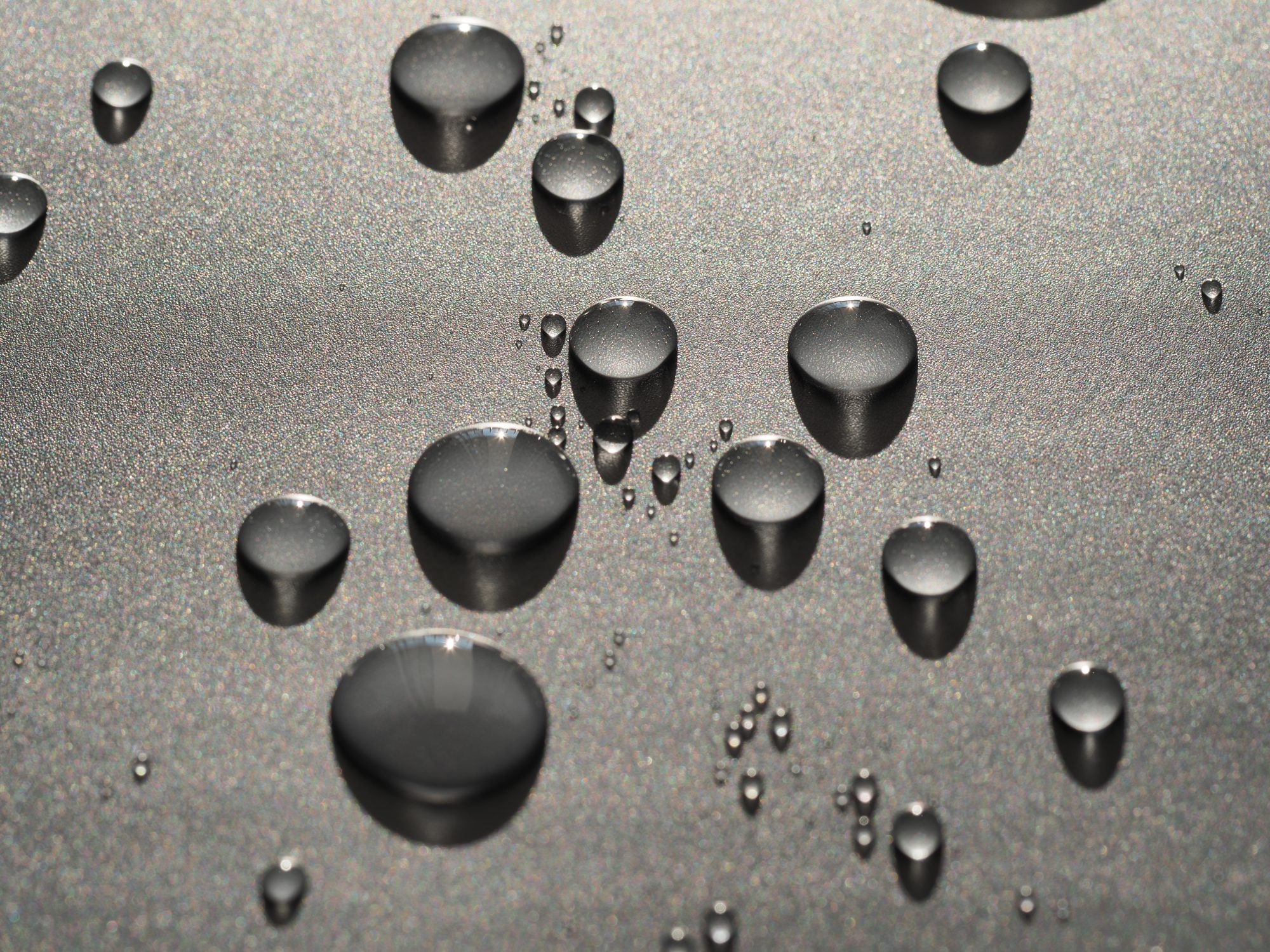

Hydrophobic coatings repel water and reduce friction between the fluid and the pipe walls. When applied, the coating creates a “slip condition” in the near-wall region of the pipe. This means less energy is required to move fluids, especially in the transition flow regime, where drag is typically higher. As a result, energy loss due to head pressure drops is minimized, leading to more efficient fluid transport.

In recent experiments, researchers tested the effectiveness of these coatings on Polyvinylchloride (PVC) pipes. They found that hydrophobic coatings significantly reduced drag, especially when the fluid moved at moderate Reynolds numbers. This reduction in drag can help extend the life of pipes and reduce energy costs.

The Game-Changing Role of DragX

Among hydrophobic treatments, DragX stands out. It not only provides an excellent reduction in friction but also improves overall flow efficiency. With DragX, pipelines can achieve smoother fluid flow without needing constant maintenance or reapplication, which is often required with other drag-reducing agents (DRAs).

Unlike additives, which must be continuously injected into the fluid, DragX is applied directly to the pipe during manufacturing. This long-lasting solution means reduced operational costs over time. Plus, by avoiding chemical additives, DragX helps maintain a cleaner system, especially in industries where water purity is essential.

Benefits of Hydrophobic Coatings for Energy Efficiency

By reducing energy consumption, hydrophobic coatings like DragX offer clear environmental benefits. Lower friction means less energy is required to pump fluids through the system, reducing greenhouse gas emissions. This aligns with global efforts to cut down carbon footprints in industrial operations.

Furthermore, using DragX in pipeline systems is a practical solution for industries ranging from oil and gas to water treatment. Whether transporting oil, gas, or water, DragX ensures efficient flow, lowering both energy costs and maintenance needs.

Future Potential

The potential for hydrophobic coatings is enormous. With ongoing research, we can expect even greater energy savings and operational efficiency improvements. As industries continue to focus on sustainability, solutions like DragX are likely to play a pivotal role in achieving these goals.

Incorporating hydrophobic coatings such as DragX in pipelines offers a smart, cost-effective way to reduce energy consumption and improve efficiency. With its ability to decrease drag, cut energy costs, and promote sustainability, DragX is the future of pipeline management. Investing in this technology today means saving money and helping the planet tomorrow. Learn more about DragX with our experts.