Steel pipelines are essential for transporting oil, gas, and other critical resources, but corrosion remains a significant challenge. Corrosion can compromise pipeline integrity, leading to costly repairs, environmental damage, and safety concerns. Nanotechnology has emerged as a game-changer in managing these challenges. By applying nanocomposite surface treatments, such as DragX, industries can greatly enhance pipeline longevity and reduce operational costs.

The Growing Importance of Nanotechnology in Corrosion Protection

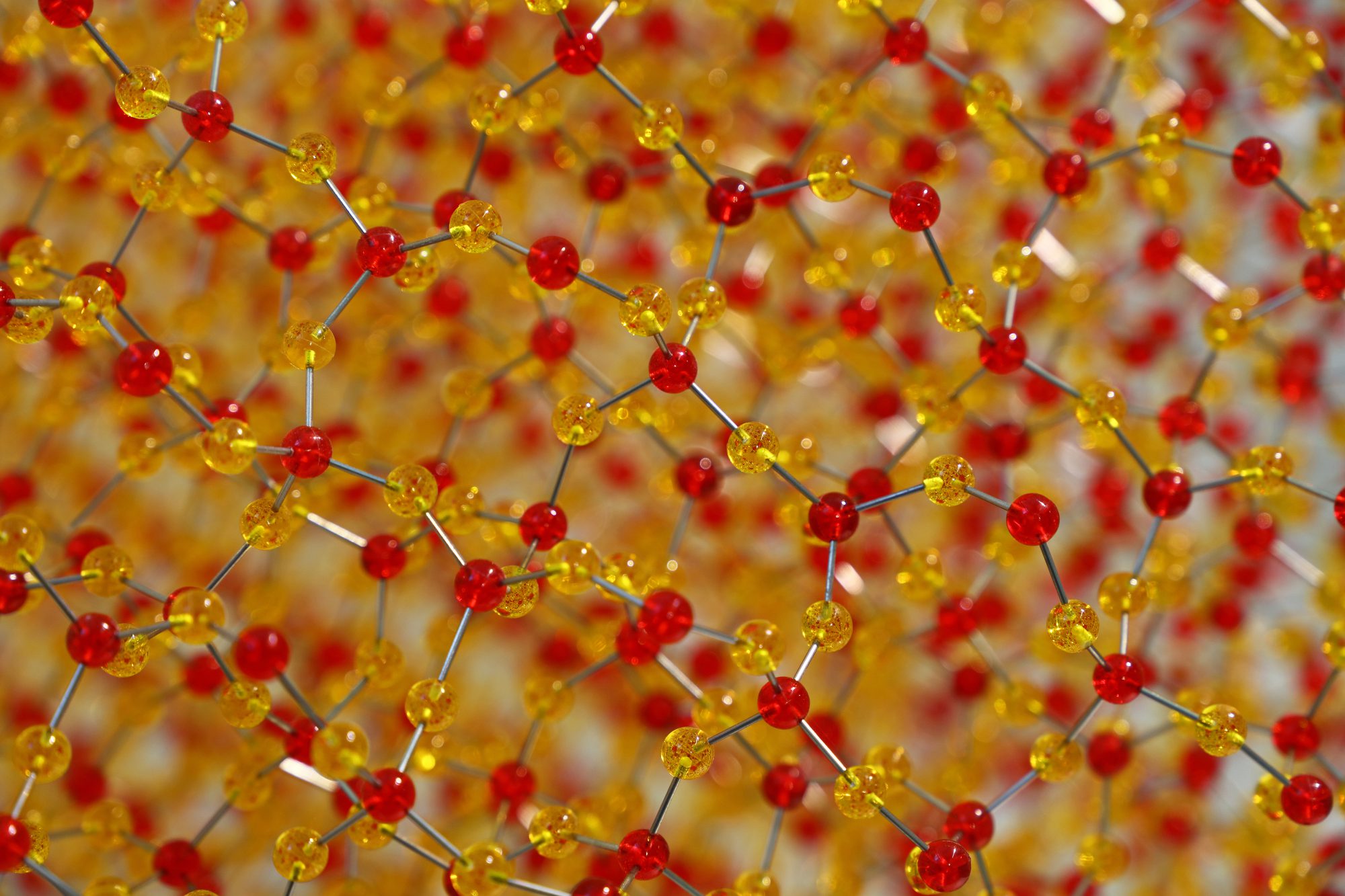

Nanotechnology involves manipulating materials at a near-atomic scale, producing innovative solutions that improve corrosion resistance. Nanocomposite surface treatments work by embedding nano-sized particles into a protective layer, forming an advanced barrier significantly reducing corrosion. The unique properties of nanomaterials, such as their small size and high surface energy, make them ideal for enhancing traditional coatings.

Why Steel Pipelines Need Advanced Surface Treatments

Steel, commonly used in pipelines, is prone to various forms of corrosion, including pitting and stress corrosion cracking. These can occur in harsh environments, such as those found in oil and gas industries, due to exposure to moisture, temperature fluctuations, and corrosive agents. Traditional protective methods like cathodic protection or metallic coatings have been effective but often require frequent maintenance. Nanotechnology provides a superior solution by creating stronger, longer-lasting surface treatments.

DragX: A Leading Nanocomposite Surface Treatment

DragX is an innovative example of how nanotechnology can revolutionize pipeline protection. This surface treatment employs nanocomposites to form a tough, corrosion-resistant layer on steel pipelines. The incorporation of nanoparticles enhances the hardness of the material, reduces friction, and increases overall durability. This means DragX can prevent both external and internal corrosion, extending the lifespan of pipelines and reducing the need for constant maintenance.

How Nanocomposite Surface Treatments Like DragX Work

Nanocomposite surface treatments alter the chemical composition of the steel at a nanoscale, creating a finely crystalline microstructure that improves corrosion resistance. The nanoparticles in DragX act as a barrier, preventing moisture and corrosive elements from reaching the metal surface. These advanced coatings also maintain a clear, smooth surface, reducing buildup and wear over time.

Benefits of Using DragX for Steel Pipelines

- Superior Corrosion Resistance: Nanoparticles form a tight barrier, preventing corrosive elements from attacking the steel surface.

- Durability: The nanocomposite surface increases the material’s toughness, reducing the impact of environmental stressors.

- Cost Savings: By reducing the frequency of repairs and maintenance, DragX provides a long-term solution that cuts operational costs.

- Environmental Protection: Enhanced corrosion protection reduces the risk of pipeline leaks, safeguarding the environment from hazardous spills.

Nanotechnology, particularly through nanocomposite surface treatments like DragX, is transforming how industries approach corrosion protection. By enhancing steel pipeline durability and providing long-lasting protection, DragX offers a sustainable, cost-effective solution to one of the most pressing issues in industrial operations. Investing in such advanced surface treatments can significantly improve the lifespan of pipelines and reduce the environmental and financial impact of corrosion. Reach out to Oceanit’s experts to learn more about DragX.